With the help of architectural practice Uenoa, screw manufacturer Synegic now has a magnificent showcase for what can be achieved with the company’s products. The new headquarters, surrounded by leafy trees in the small town of Tomiya, neighbouring the much larger city of Sendai, is a marvel of exciting architecture.

“When we were commissioned, the client asked us to create advanced architecture that expands the horizons of what can be achieved with wood. From this, we drew up the design for this building, with its unique timber structure,” explains Fumie Horikoshi, architect and co-owner of the Tokyo-based practice Uenoa.

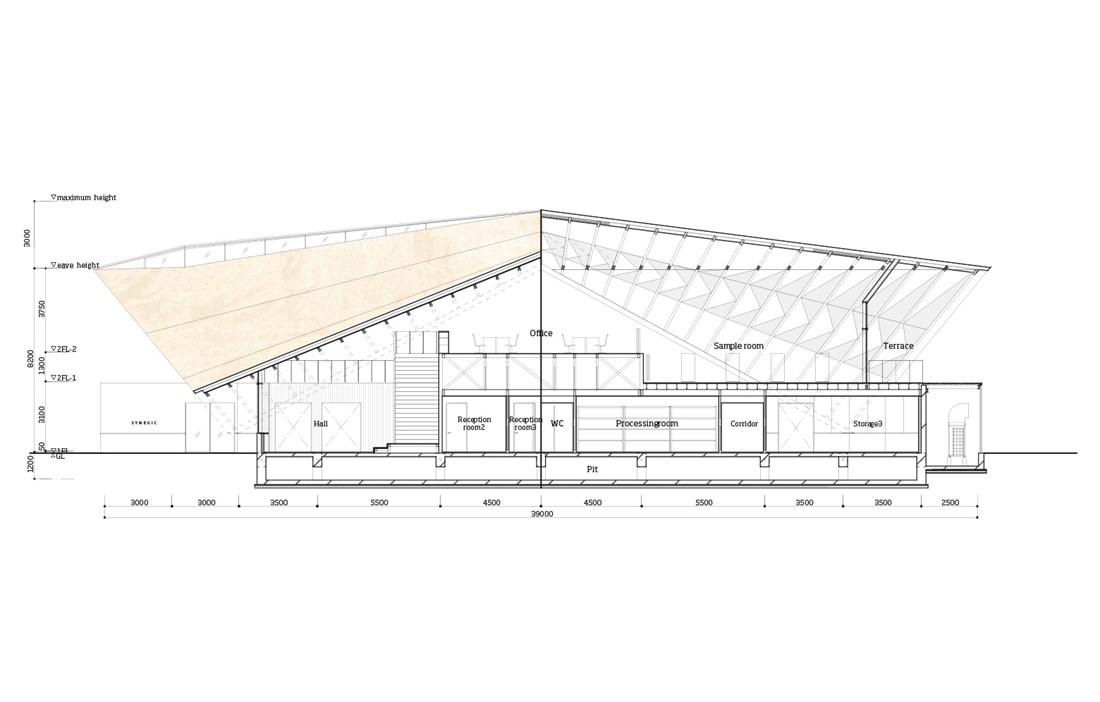

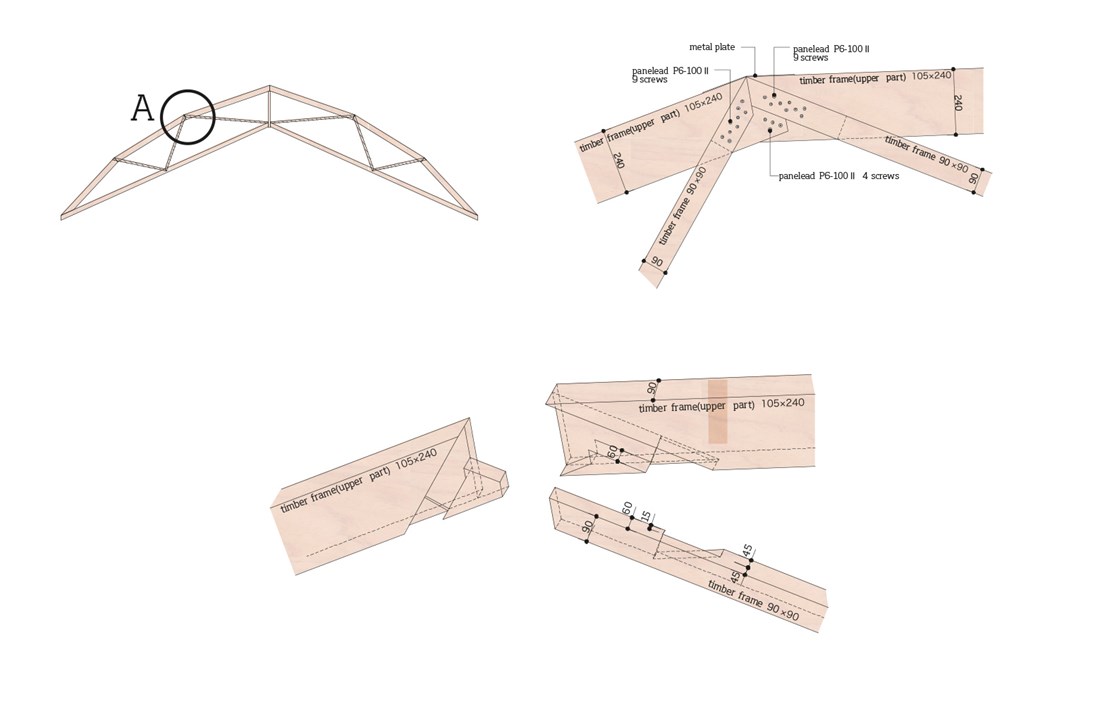

The eye is drawn to the geometrically advanced roof, which comprises two layers of triangles. The widest triangles have a base that reaches all the way from side to side and comprise a framework of glulam beams made from Japanese pine. The dimensions of these are 105x240 millimetres, a common size in Japanese buildings. Above the lower part of these trusses sit two long rows of triangular CLT panels in Japanese cedar, like two flights of birds lowering their wingtips from the top of the roof down to the glulam beams. Where the wingtips meet the beams, both elements are connected with fixings at the centreline and two outer lines. Behind both structures, the roof is lined with longitudinal cladding in European red pine.

“By using CLT, which generally tends to be used for walls and floors, we were able to achieve a structure that was at once light, strong and effective. An alternative would have been to use beams here as well, but that would have made the nodes much more complicated. Instead, it was relatively easy to deal with these using CLT and screws – almost all of which were Synegic’s own Panelead screws,” says Fumie Horikoshi.

Another advantage of the CLT structure was that it allowed for a rational method in which many elements could be prefabricated and then assembled on site.

The design removes any need for posts in the middle of the 18 metre wide building, which creates a sense of space and offers good visibility.

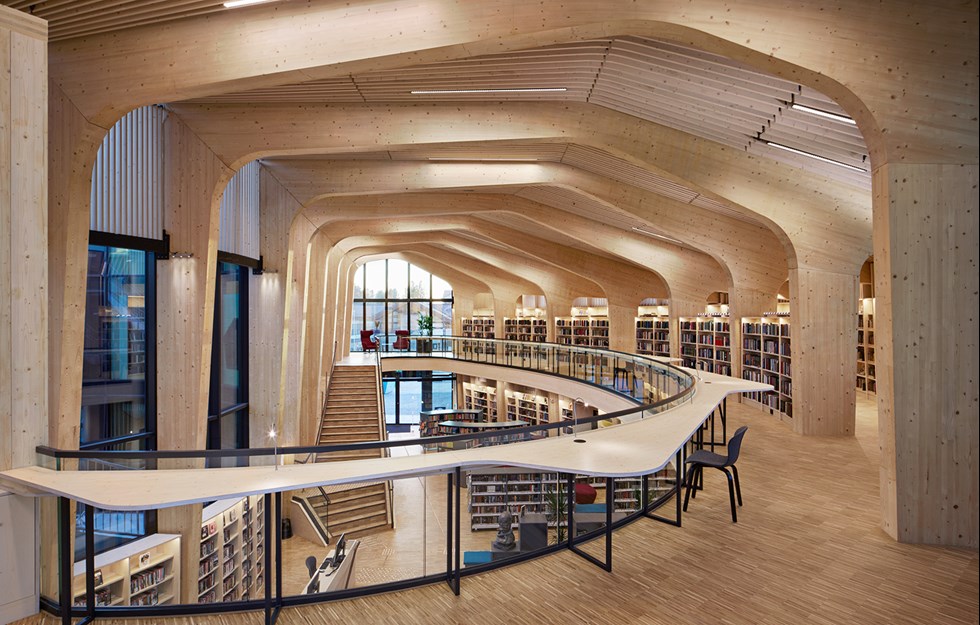

“We didn’t want the beautiful timber frame, which is so significant for the appearance, to be something you only look up at. So we created multiple floor levels and extended the roof down to the ground at four points. This creates areas where you’re close enough to touch the roof, while at the same time you get the sense of volume and monumental scale in the middle of the room,” says Fumie Horikoshi.

The trusses and triangular CLT elements continue outside, as the roof extends out over the façade. On the exterior, the roof is finished with a patchwork of small copper tiles. These give the impression of landing softly on the underlying wooden structure, like a piece of folded paper that drapes gently towards the ground.

The external walls, internal walls and roof are structurally completely separate from each other, with the load-bearing inner walls made of CLT and the outer walls of steel. On the first floor there is also an extra partition wall in CLT that takes some of the vertical load. An important reason for keeping the different parts separate is to make future maintenance and renovation easier. In Japan there are also several restrictions placed on large wooden buildings, many of them aimed at fire prevention.

“If you use wood internally, you have to have a fireproof outer wall that is independent of the interior. This is why the external walls are made of steel, coated with an extra layer of fireproofing,” explains Fumie Horikoshi.

Around 35 people work in the building that is now Synegic’s head office. The workspaces are spread across two floors, with a mezzanine in between. The interior is designed to meet the company’s need for different ways of working. There are office spaces with desks, and enclosed areas that are good for experiments and collaborations with external researchers. The open spaces create an inspiring environment that invites cooperation, encouraging employees from different parts of the company to engage with each other. There is an abundance of airy space, while the surrounding wood creates a warm, intimate and comfortable feel.

“I’ve also had several of the company’s employees telling me how happy they are to be working in such an uplifting environment. And they find it inspiring to see their own products used in the building,” adds Fumie Horikoshi.

On the back of this success and the experience of working with CLT in new ways, he sees opportunities for more projects like this in the future. This is also closely aligned with Uenoa’s philosophy of working with sustainable methods and striving for uniqueness in their projects.

“The people at Synegic have told us they have many visitors from the wood and construction industry coming to look at the building for the advanced wooden structure that it is,” says Fumie Horikoshi.

Text Sara Bergqvist